Description

When using the car on the track the cornering forces are bending the rubber in the wishbones (control arms). Thus changing the desired geometry of the car. This can lead to slower track times and ineffective tire usage.

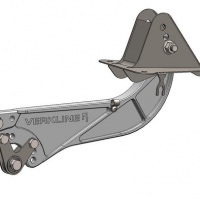

For that reason, we have come up with uniball control arms. Our race wishbones use metal to metal uniball just like used in Porsche RS line (GT2RS, GT3RS). Tested intensively on our Track Audi TTRS.

We are using the same T45 tubing as in WRC cars, our wishbones provide increased stiffness and extra adjustment. All factory parts bolt up to this unit, no other modifications are necessary.

Product functionalities:

– Adjustment both caster and camber (up to -4.5 degrees)

– no rubber to bend, you will not loose the geometry set when doing aliment

– works with OEM subframe and our tubular subframe

– enables removal of the wishbones with our the need for removal of the subframe

Features:

– T45 (BS4T45 to BS4T100) tubing imported from UK and S355 metal sheets

– proven motorsport M18 uniballs (the same type we use in our Lancer EVO X kits)

– plug and play to use with the car inc xenon sensors

What is included:

– two (pair) front wishbones (control arms) with all hardware for install

– four rubber caps for uniball protection

– printed install instructions

Used in cars (type numbers in brackets):

-

2012 – Audi A3/S3/RS3 (8V and 8VFL MQB)

- 2015 and up – Audi TT/TTS/TTRS (8S)

- 2012 – Volkswagen Golf/GTI/R (Mk7 MQB + Mk8)

- 2012 – Seat Leon (5F MQB)

- Other MQB-based models

T45 is a very unique seamless carbon-based steel tube that has been used in many applications in different industries. It is stronger than Co-Mo 4130 tubing that also used in motorsport. It is widely used in the aerospace sector in equipment such as pilot’s seats and crew’s seats due to the material’s ability to withstand high G forces without snapping or splitting. This material is a Carbon Manganese based and conforms to the full Aerospace Specification laid down by British Standards.

Properties

Tensile: 700 – 900MPa,

0.2% Yield 620MPa minimum

Hardness Test: 201min – 262 max HB or 210min – 275max HV.

Note: Sold for off-road, track and racing applications only. Installation of this rear arm kit might introduce some additional some NVH (noise, vibration, and harshness) transfer into the cabin.

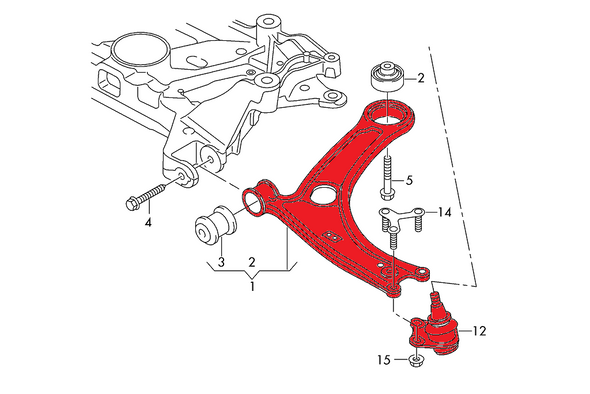

Replaces:

– 5Q0407151 and 5Q0407152

– 81A407151C and 81A407152C

– 8S0407151D + 8J0407365 or 8J0407366

vibration, and harshness) transfer into the cabin. Replaces: – 5Q0407151 and 5Q0407152 – 81A407151C and 81A407152C – 8S0407151D + 8J0407365 or 8J0407366

Reviews

There are no reviews yet.