Description

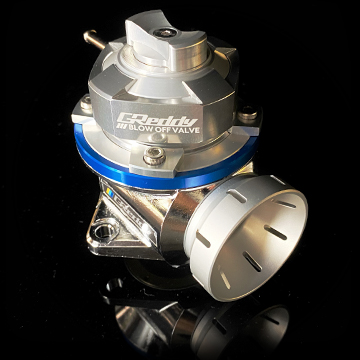

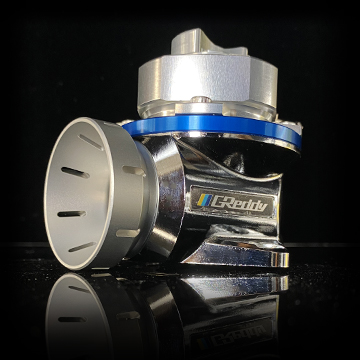

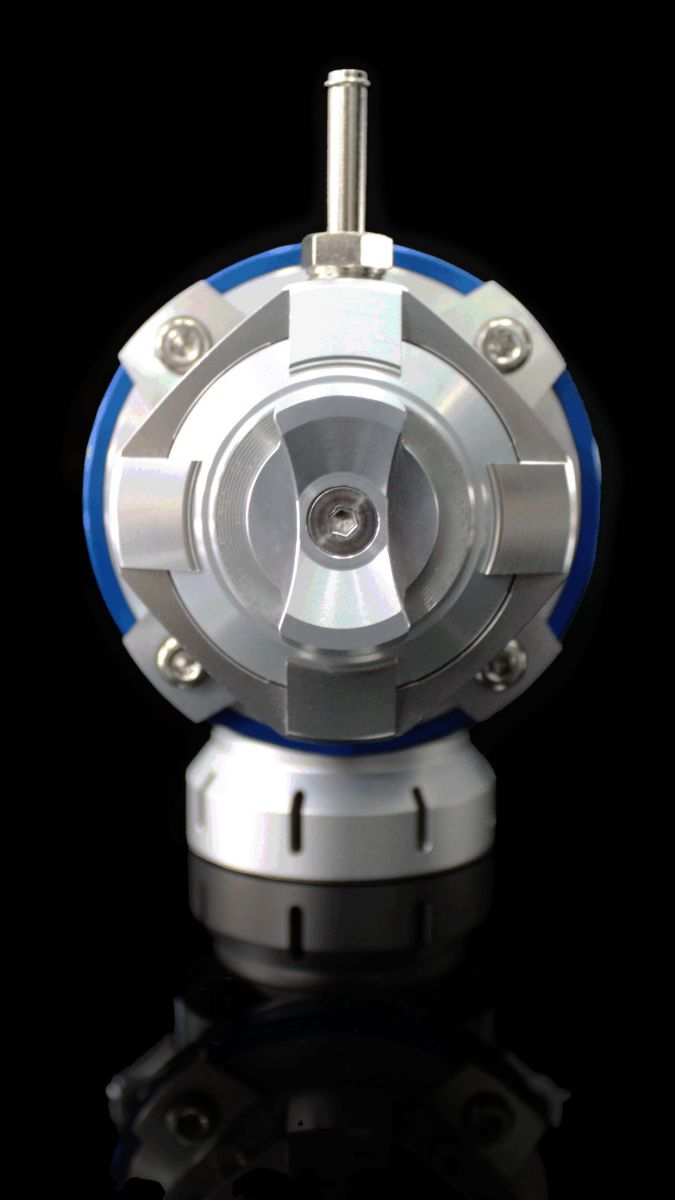

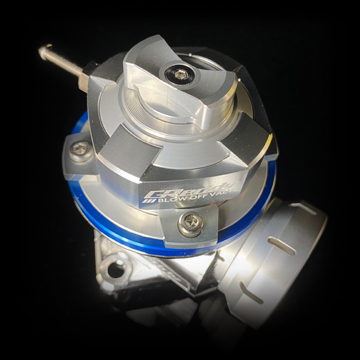

“GReddy BLOW OFF VALVE TYPE-FV2” inherits the floating valve structure that was popular in the previous FV model, while improving with a more sophisticated design, easier adjustment, and even more reliability.

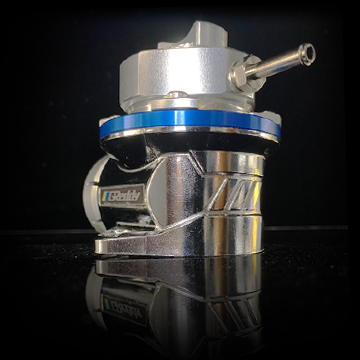

A hand turning detent knob that adjust the preload setting of the spring does not require any tools. It is also now possible to change the direction of the hose union on the top cover, so it can also be adjusted 360°, also without tools, to best suit your installation.

The mounting flange and inlet retain the same dimensions as previous GReddy blow-off valves (TYPE-RS, RZ, and FV) so the TYPE-FV2 can easily replaced any of the older models.

BLOW OFF VALVE TYPE FV2

■ Product name:GReddy blow-off valve FV2

■ Part Number:11501666

Also available are application specific bolt-on kits for popular applications: R35, R32/R33/R34, ECR33, HCR32, S14/S15, JZX100, JZA80, ZN6 Turbo, GDB, GRB, CT9A, CZ4A, FD3S and more…

Click here to download the instruction manual – (instruction manual)

Specifications:

■ Prevents idling problems that can tend to occur with other blow-off valves.

The floating valve mechanism allows the valve to react quickly because there is no need to apply unnecessary excessive preload to the spring.

■ Quick response even at low boost situations.

The floating valve mechanism prevents premature opening and closing of the valve.

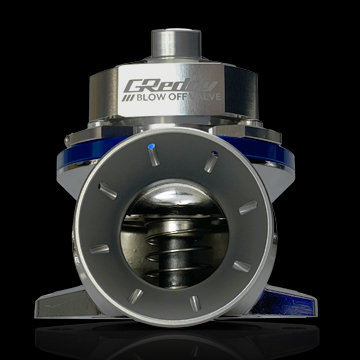

■ Uses a floating valve structure (FV = ” Floating Vavle”)

By adopting a floating valve design, the diaphragm and valve operate independently, in this way it is possible to achieve a valve response that exceeds that of the previous models and a stable blow-off situations throughout a large boost range.

■ Uses a new rotation-adjustable top-hat.

The 360 ° adjustable top cover eliminates the need to disassemble the top hat, to changing the orientation of the hose union. This greatly improving usability and ease of installation, compared to previous models.

■ Preload adjustment with detent adjustment knob.

The easy-to-rotate detent adjustment knob makes it easy to adjust the preload with precision, given its large adjustment range (about 5 full rotations – Lock to lock) without the need for any tools.

Operation of blow-off valve FV2

■【When the throtle is open】

The dual valve spring, boost pressure from the surge tank or intake manifold, and support spring strongly press the valve to prevent relief during high supercharging.

■【When the throtle is closed】

The surge tank pressure becomes the maximum negative pressure, the diaphragm and dual spring are pulled up, and the valve is released. The valve pressed only by the support spring is pushed up by the residual pressure in the pipe, and the residual pressure is released instantly.

■【When the throtle is closed (after blow-off)】

Even if the pressure inside the surge tank remains negative and the diaphragm is pulled up, the support spring closes the valve quickly when the residual pressure is released to prepare for the next accelerator ON. This will launch the boost quickly.

■ Blow-off valve FV2 optional parts